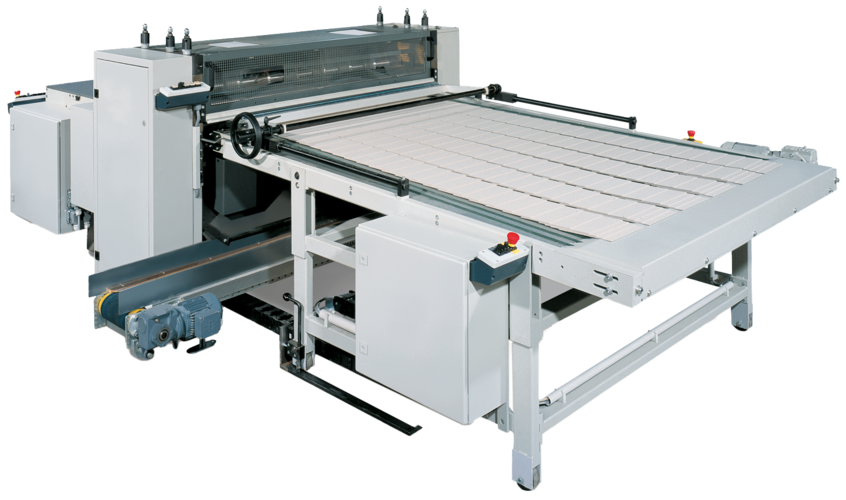

Rotary Board Cutter PK 170

Machine for perfect cardboard blanks for the production of book covers, game boards and packaging

The KOLBUS Rotary Board Cutter is for perfect cardboard cutting for the production of bookcases, game boards, and packaging. Further processing into box covers with sharp edges can be done with a grooving machine and BOX LINE modules. The PK 170 cuts finished sections out of cardboard sheets or similar materials in two work processes with a linear cutting speed of 120 m/min, strip feed 220 cycles/min.

- Application

- Technical Data

- Benefits

- Downloads

- Media

- High-precision, accurately angled cutting of case boards at top speeds using the rotary board cutter for lengthwise and crosswise cuts

- Easy operation with steplessly adjustable feed and cutting speed

- The strip magazine for cutting blanks is quick and easy to attach

- Slippage-free board feed thanks to pull-in rolls made of an effective rubber/steel combination

| PK 170 | Min. | Max. |

| Working width (Original board format) | 600 mm | 1400 mm |

| Cutting width | 85 mm | 1380 mm |

| Finished size (width x length) | 85 x 150 mm | 1380 x 480 mm |

| Board thickness | 1 mm | 4 mm |

| Mechanical speed (linear cutting speed infinitely variable) | 30 – 120 m/min |

Net production is subject to sizes, materials, etc.

Options:

with grooving milling station:

- PK 170 with tool traverse for two continuously adjustable slot milling stations with a holder of 1 or 2 slot cutters (depending on the slot width) and dust extraction box

with inline stacking conveyor CS 171:

The machine is used for automatic stacking of finished blanks from cardboard panels on pallets.

- Pre-programmable fully automatic positioning of the format blanks on the pallet

- Monitoring of the shingle stream position

- Different pallet sizes possible

- Machine operation possible with only one person

Your contact and support

Is this not your country? Please switch to the appropriate country.